Loriol-sur-Drôme, le 08/02/2024

Revtech’s innovation for 2024: a major investment has been made in an industrial pilot unit for the food industry, propelling innovation and quality. Revtech, at the forefront of innovation in the food industry, proudly announces its major investment in 2024 with the complete modernization of its pilot plant. This project marks a significant turning point for the company, strengthening its commitment to quality and technological excellence. The pilot, equipped with 100% electric technologies, provides real heat treatment processing conditions for a variety of products, redefining transformation standards with increased efficiency, reduced heat losses, and shorter heating times. At Revtech, innovation meets customer satisfaction: every step of the process, from the technological hall to custom design, demonstrates the ongoing commitment to excellence to address tomorrow’s challenges.

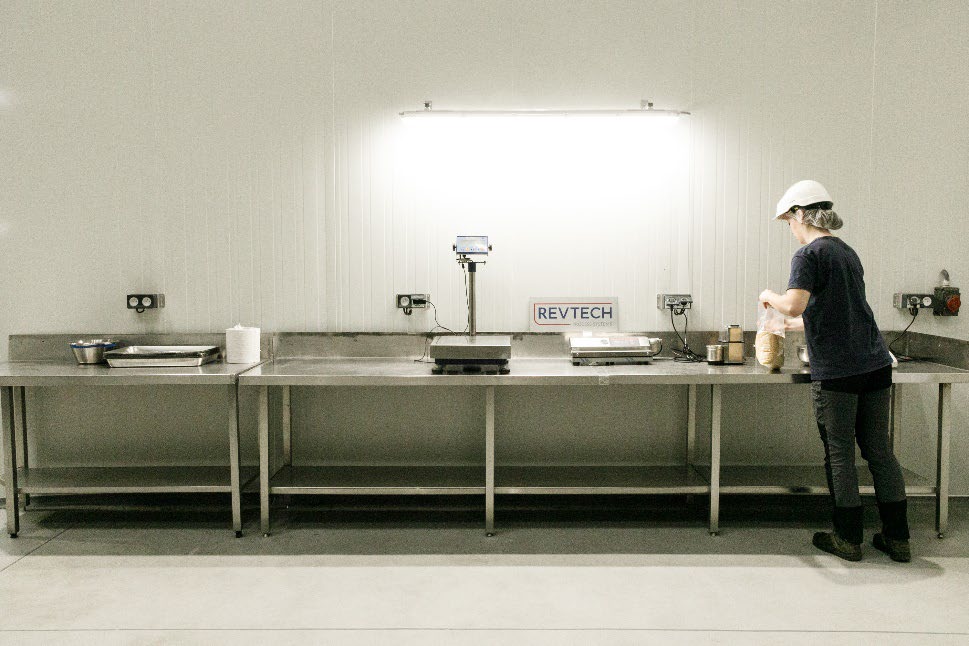

In 2023, Revtech undertook a major investment: the complete modernization of the pilot workshop, accompanied by the installation of an industrial-scale food pilot unit. The latter operates continuously and provides industrial conditions for a wide range of products and applications. This project represents a significant milestone for the company, reinforcing Revtech’s commitment to the quality of services offered to its existing and future customers. The pilot is equipped with a feeding hopper, a Revtech heating tower, a steam boiler, a hot air generator, and a vibrofluidized bed cooler. The technical features of the heating tower significantly modify conventional transformation methods, with more efficient heating, reduced heat losses, lower temperatures used, and shorter heating times.

Revtech’s technology is 100% electric, avoiding the use of natural gas, positioning the company on a current challenge: sustainable development. A special attention is offered to each customer with active participation in trials in the pilot workshop, reproducing the real conditions of their product transformation, for seeds, cereals, pulses, herbs, spices and many more. These trials, whether related to pasteurization, roasting, or the modification of functional or organoleptic properties, along with the time spent exchanging ideas, contribute to establishing a close relationship with customers.

The trials conducted allows defining optimal transformation parameters with customers: heating temperatures, residence times, product flow rates, gas injection, and many others. Samples obtained during these trials undergo thorough analysis, either internally at Revtech or with external service providers. These data are then used by the technical department to design custom-made machines meeting the specific needs of each customer.

This project was supported by BPI France with financing through a relaunch loan from Auvergne-Rhône-Alpes FEDER REACT EU and an Innovation – Research & Development loan from BPI France. At Revtech, the commitment to innovation and customer satisfaction guides every step of the process, from design to realization. This project marks a significant advancement in the constant pursuit of technological excellence for the agri-food industry.

Founded in 1997, Revtech benefits from unparalleled experience in creating industrial solutions for thermal processing and pasteurization of dry ingredients, powdery, and gaseous products. Based on various patented innovations, Revtech offers its customers a unique approach to accompany them in the accomplishment of their different projects. Thus, from conception to manufacturing, our team of experts implements a range of personalized services for the maximum return on your technological investments.